break new ground in

deep cover exploration

Introducing MPD – the ultimate high-performance

drilling technology.

Precise drilling,

extraordinary

results

As part of our commitment to finding a better way, Mitchell Services (ASX: MSV) presents Mineral Performance Drilling (MPD) – the revolutionary new technology allowing explorers to rapidly, efficiently and safely target geological sequences under deep cover, with pinpoint accuracy.

Designed in-house, MPD combines oil and gas technology with traditional mud rotary techniques, enabling mineral exploration drilling through deep cover sequences at speeds of up to 60 metres per hour.

With mineral deposits getting deeper and hidden further under cover, MPD makes it economically viable to explore, discover and drill out the orebodies of the future.

Increased safety with slow rod rotation and conventional rod handling compatibility

Hole direction monitored by steering engineer

ROP up to 60m/hr in sedimentary formations

Live data feed to surface from

bit face

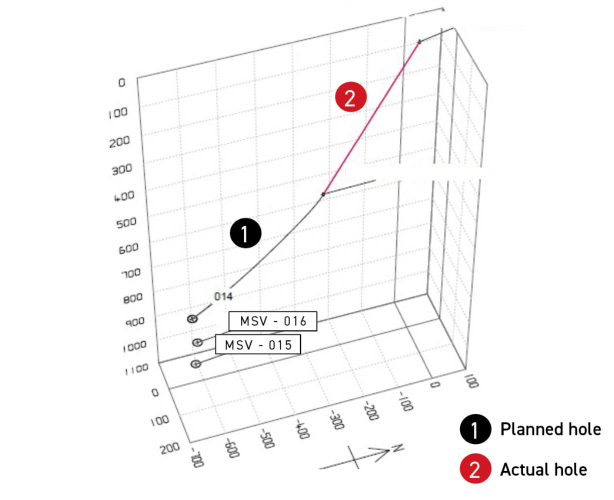

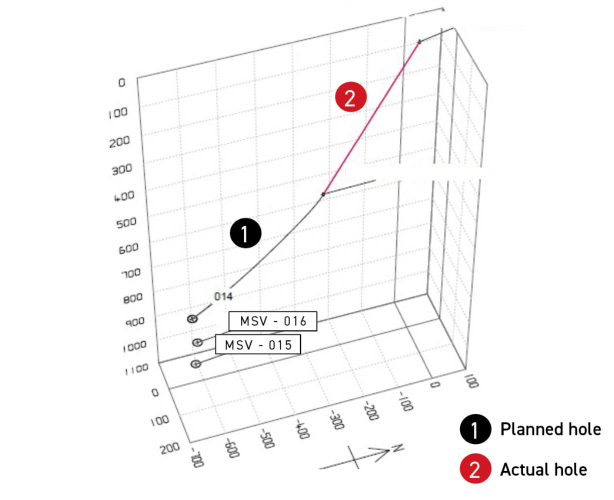

Live tracking of hole flight paths versus plan

-

Increased safety with slow rod rotation and conventional rod handling compatibility

-

Hole direction monitored by steering engineer

-

ROP up to 60m/hr in sedimentary formations

-

Live data feed to surface from

bit face -

Live tracking of hole flight paths versus plan

Drive progress to new depths

With MPD, no target is out of reach. This cutting edge technology is designed to get more

out of every hole, locating deep geological formations with greater speed and accuracy.

Productivity

MPD combines various drilling technologies

to deliver rates of penetration up to

60 metres per hour in certain sedimentary

cover sequences.

Safety

When MPD is operating, the rod string

spins at very low revolutions. Rods are

also handled using the rig’s rod handling

equipment, minimising hands-on-steel.

Directional

Control

Along with significant levels of

production, holes using MPD are

directionally controlled to hit target

zones within centimetres.

Real-Time Hole

Tracking

Data is delivered from the drill bit

to the directional engineer in real

time, so holes can be tracked live

to provide piece of mind.

Commercial

MPD allows our clients to get their

data to market or to make informed

decisions faster. This is a critical

benefit as laboratory turnaround

times continue to increase.

Environment

MPD does not require large drill

pads to operate. Standard diamond

drilling pads and sumps are all

that is required.

mpd rig package

Bringing enhanced direction and design to drilling technology, the MPD rig package

leaves traditional setups out of their depth.

Traditional

rig setup

- Multipurpose rig package

- Mud rotary tooling

- Mud pump

- 20m x 20m drill pad

- Standard sumps

- Performance mud motor

- Specialist PCD bits

- Directional software

- Steering engineer/s

- Hole designs